Manufacturing Data Software

We have an online demo of a cement manufacturing system.

Our manufacturing software is tailored to each customer and applies to many industries, not just cement!

We can import data automatically from your PLC/HMI systems to reduce data input burden, allowing your personnel more time to focus on what matters. At its core, our software is designed to track your inventory, production, material usage, equipment reliability, quality control data, and more!

We can import data automatically from your PLC/HMI systems to reduce data input burden, allowing your personnel more time to focus on what matters. At its core, our software is designed to track your inventory, production, material usage, equipment reliability, quality control data, and more!

Keep scrolling for more detailed information!

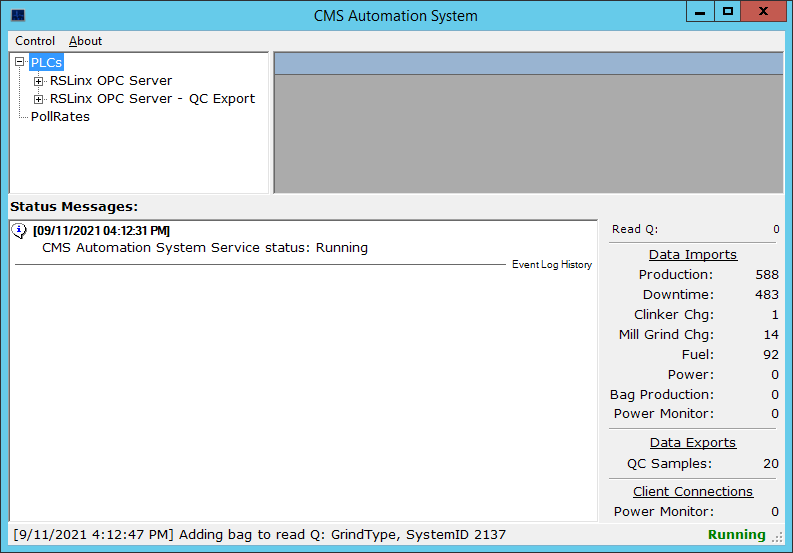

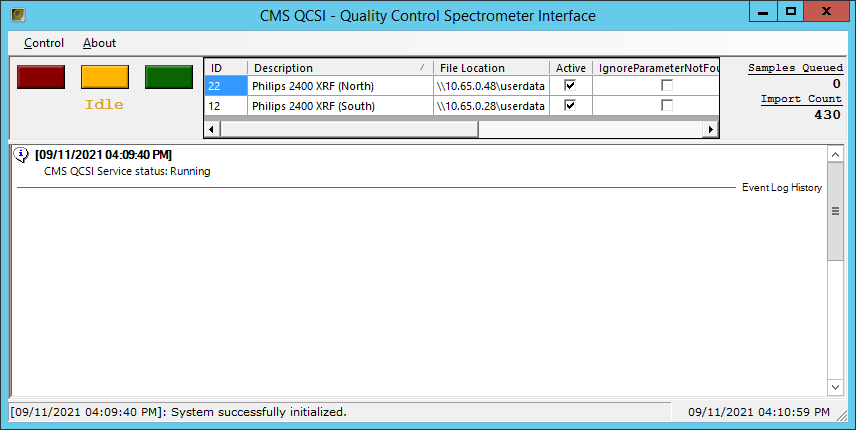

Automated Data Import

Import data automatically from your control systems to reduce data input burden.

- Our software can import data from a number of control systems such as PLC networks and HMI systems.

- Automatically detect when equipment goes down, making reliability tracking simple!

- Highly configurable - make use of production factors to automatically account for things like moisture and material loss.

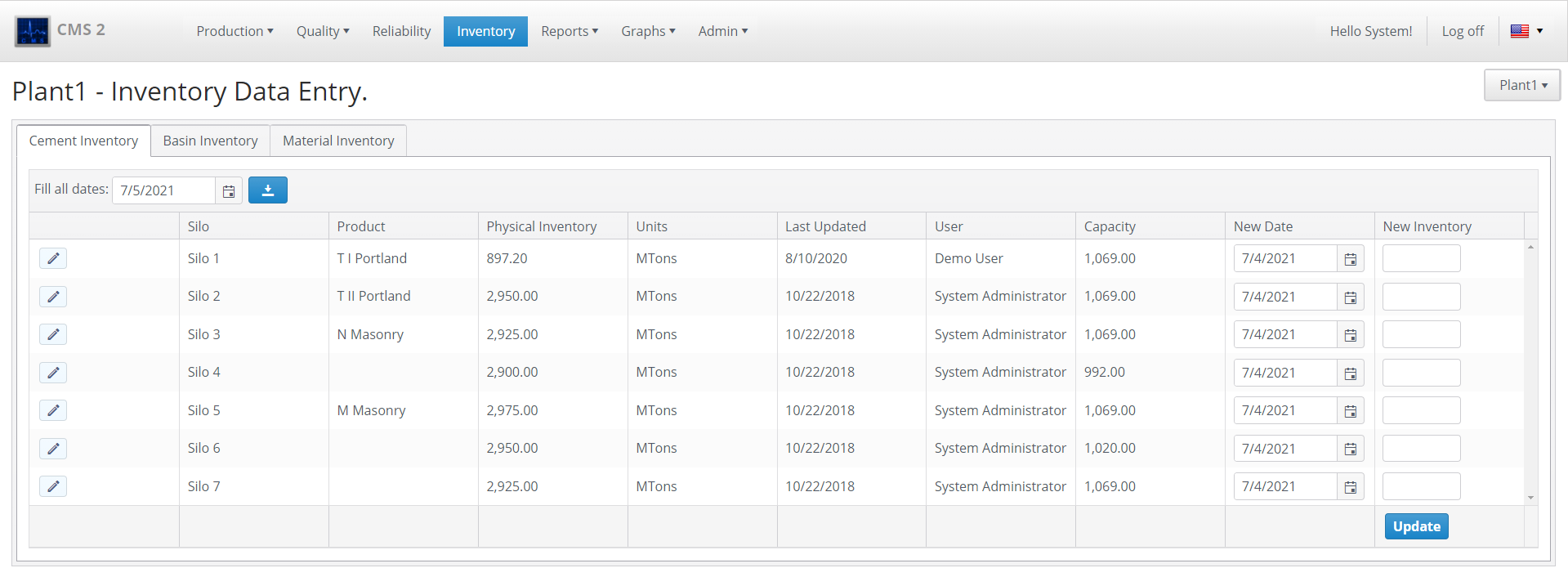

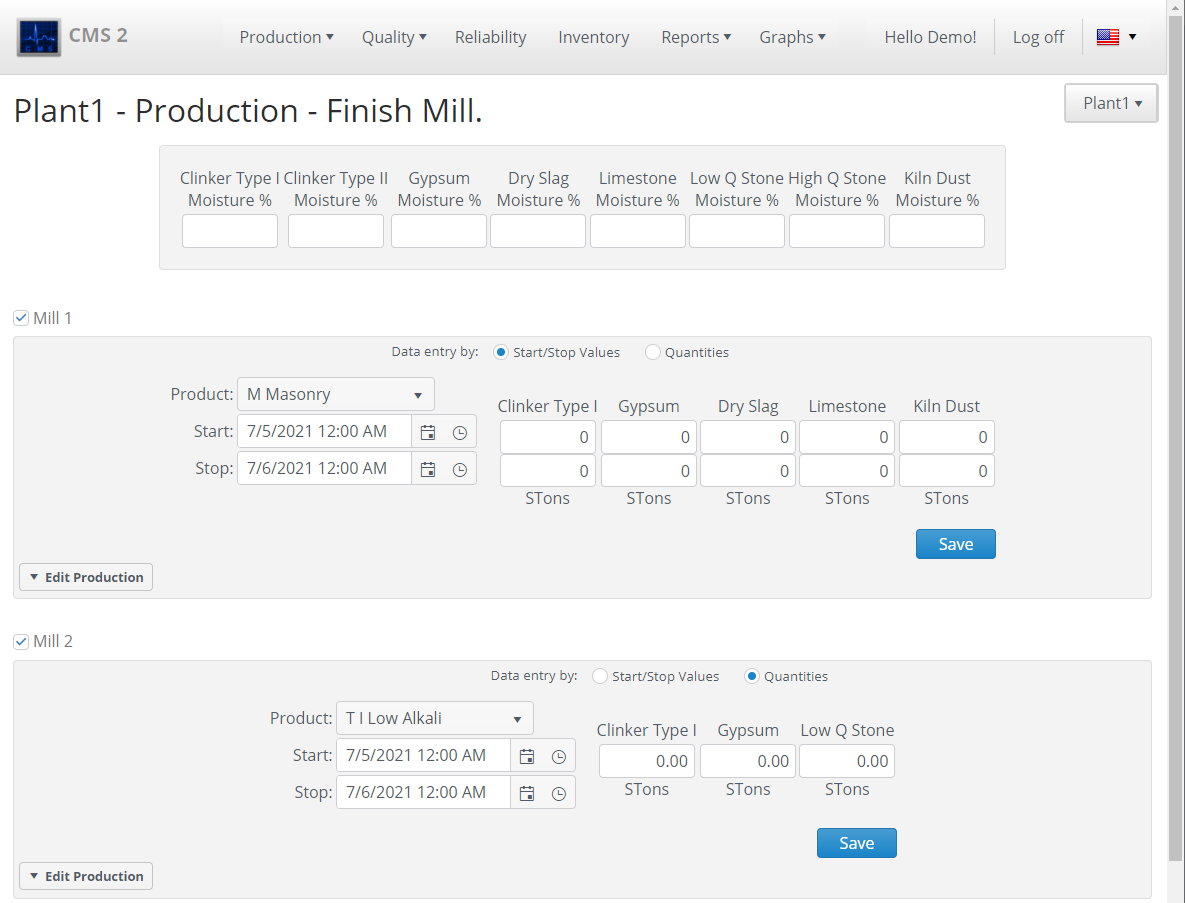

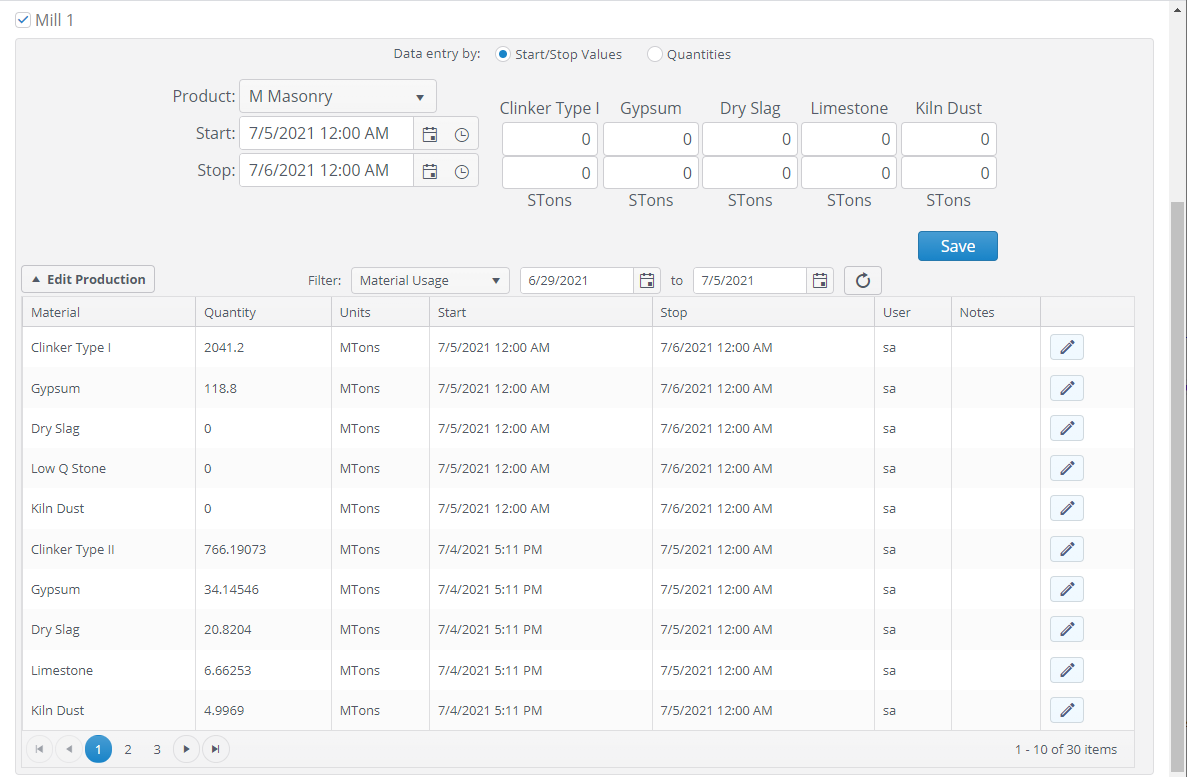

Inventory, Production, and Material Usage

Our software allows you the peace of mind knowing that what you have, and what you're producing, are accurate with a reconciliation process that helps identify data inconsistencies.

- Intuitive data entry interface makes quick work of daily duties!

- Highly customizable - you control what each system uses, by end product, and how it's entered.

- Quickly identify and easily correct data entry errors.

- Endless configuration options - configure factors for equipment, like material feeders, that may not have accurate accumulators or totalizers.

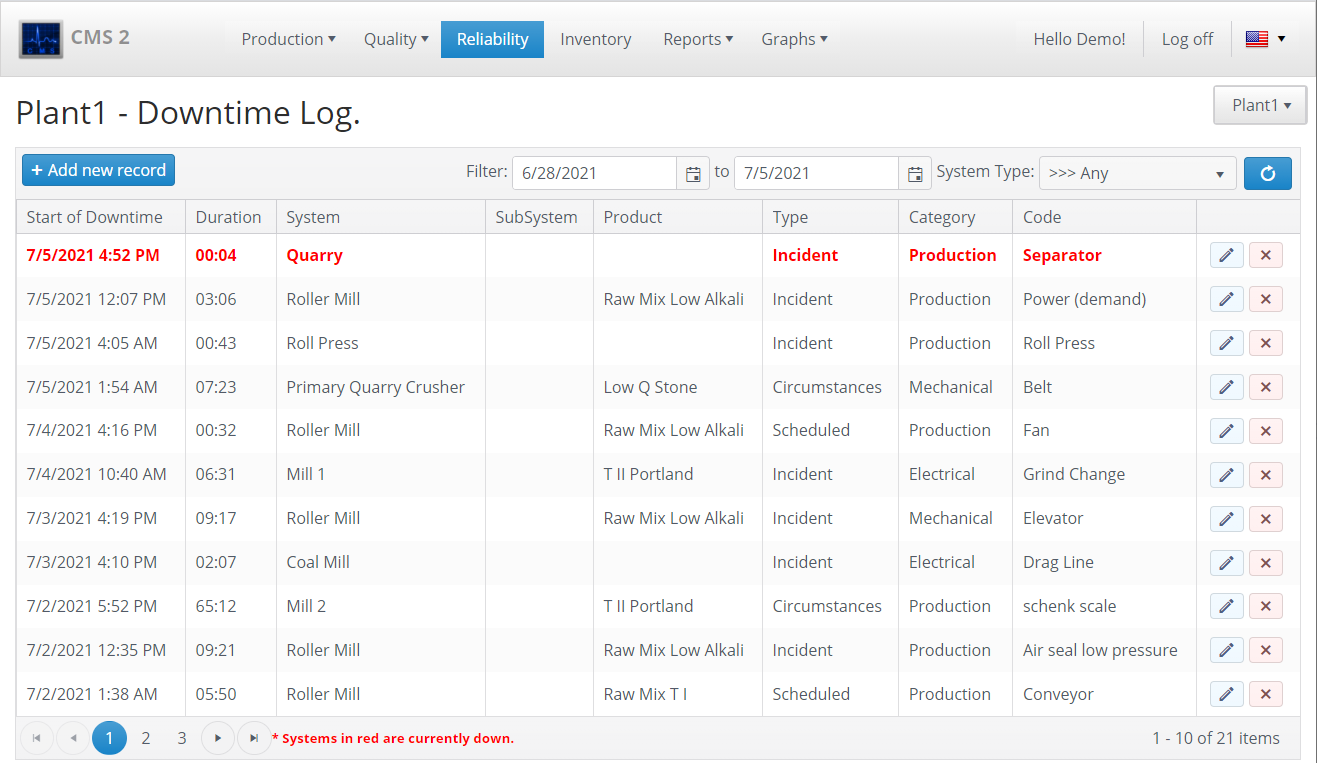

Equipment Reliability

Track equipment down time and causes, and analyze how they impact production and quality trends.

- Track your equipment's effectiveness using industry standard measures like MTBF, OEE, and more.

- Highly customizable - configure any number of downtime categories and codes to properly classify down events.

- Support to specify "subsystems" to allow you the ability to identify the equipment that leads to the most down time.

- Comprehensive reports allow you to both see detailed information about the down events as well as to summarize equipment reliability.

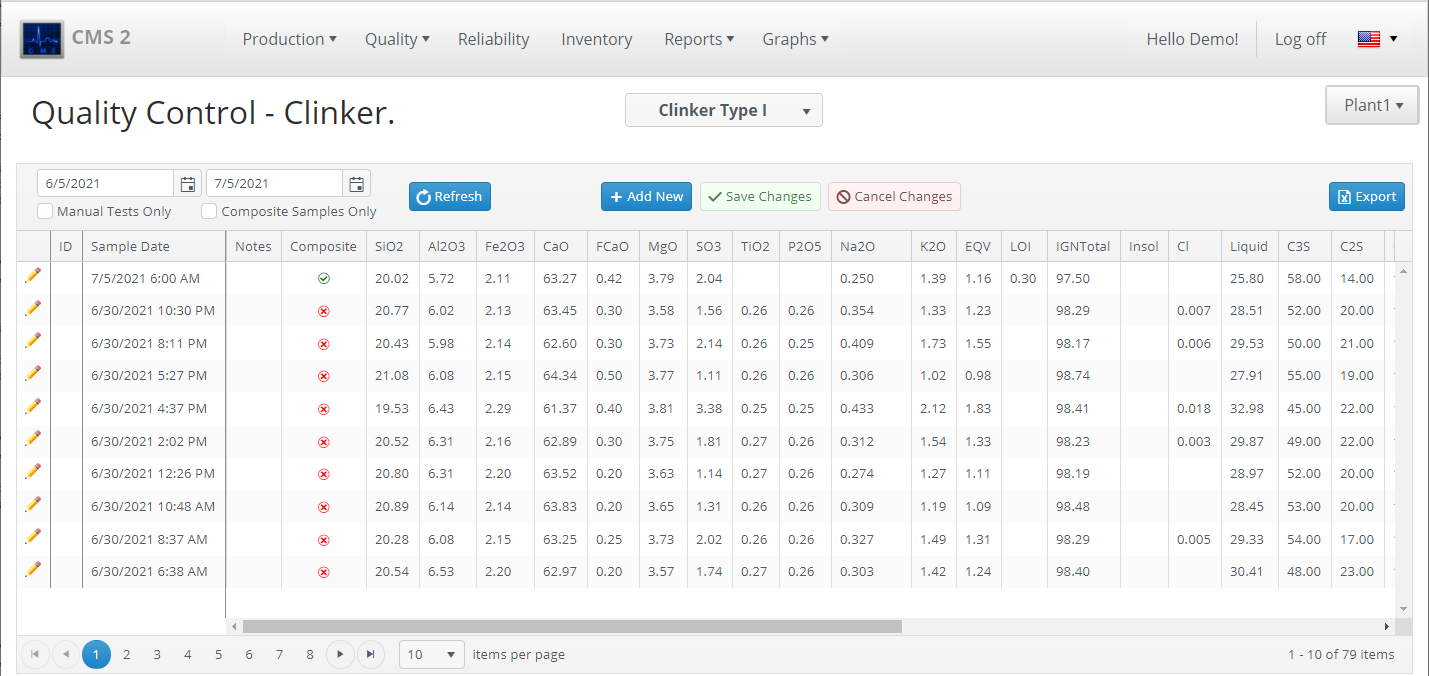

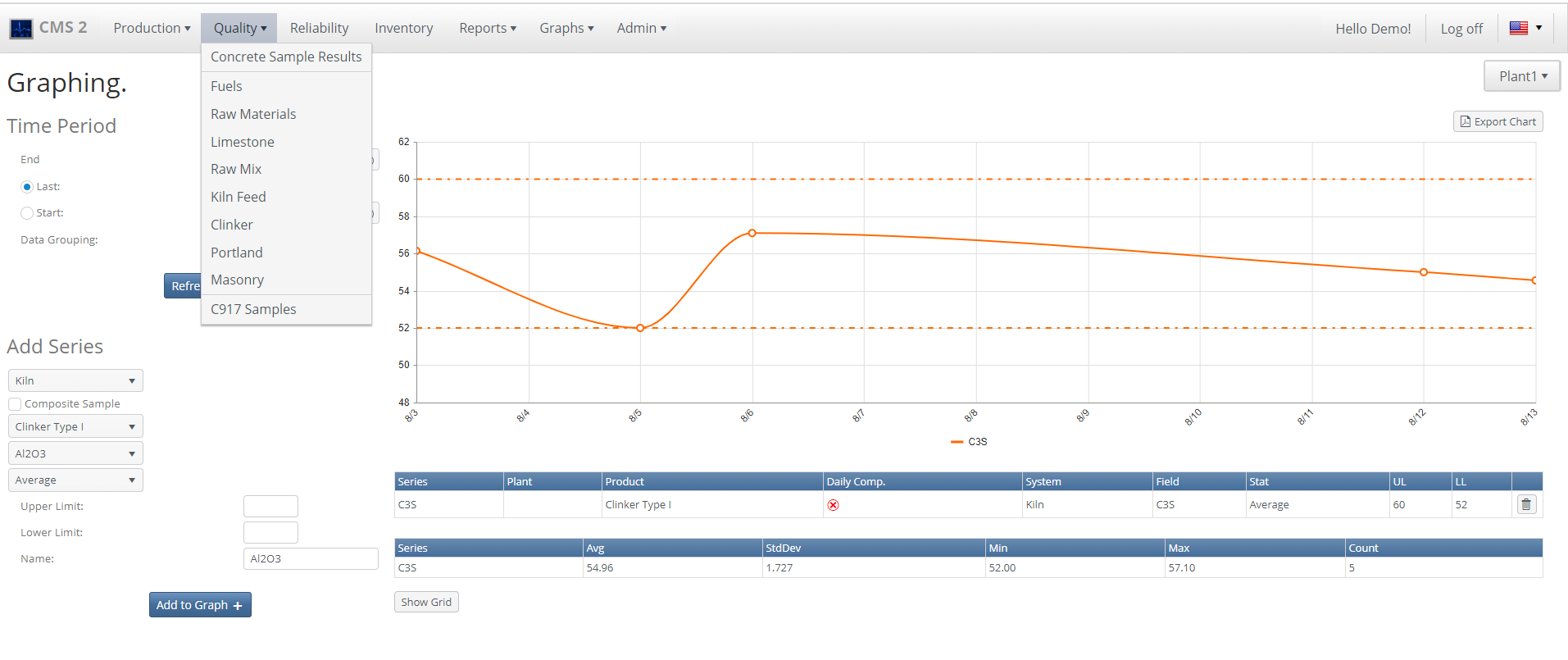

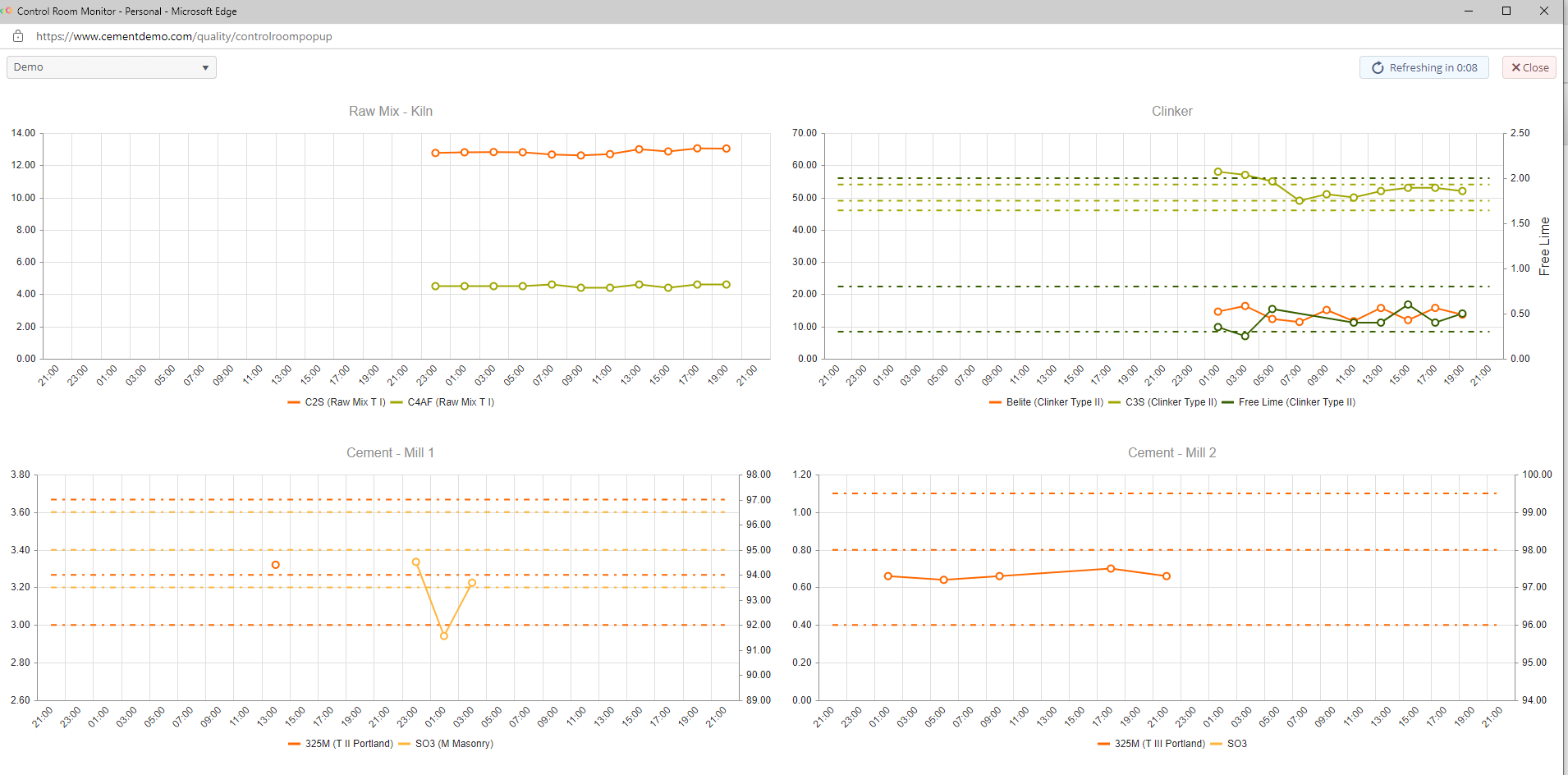

Quality Control

Automatically import test results from lab equipment, enter physical test results, and report on quality trends and how they compare to your quality objectives.

- Import sample results from a multitude of lab equipment like x-ray spectrometers.

- Highly customizable - you control which parameters are shown, by material type.

- Set targets to better visualize the quality of the materials you're analyzing.

- Configure alarms to automatically email a distribution list when results are above or below a particular target for a configurable number of consecutive samples.